Build You a Competitive 2WD "Small Tire", 4WD "Small Tire", or a 2WD Pro-Street Mini Pulling Truck -

These

type of small pulling trucks would not cost nearly as much to build and maintain

as a traditional full-size (and high dollar) pulling truck. And it would

probably cost about the same or maybe less to build a 2WD or 4WD small wheel

pulling truck than it would cost to build a competitive garden pulling tractor.

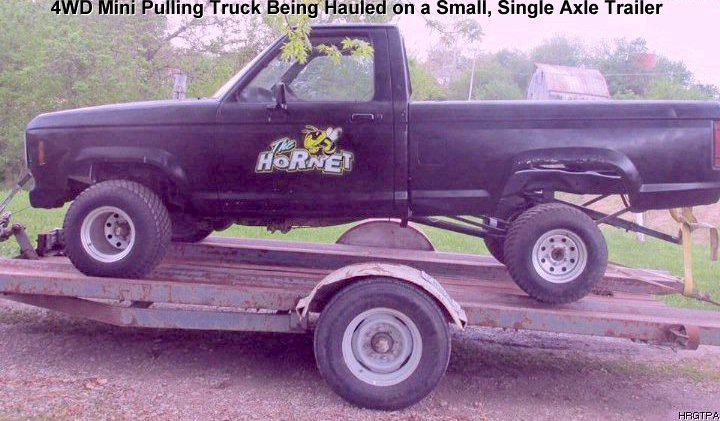

In addition, unlike the full-size pulling trucks, which require a large,

heavy towing vehicle and a heavy duty goose-neck trailer to haul the truck

to and from the pull sites, these small and light-weight mini pulling trucks

require just a newer/late model 1/2 ton pickup truck (which have better braking

than earlier/older trucks) and a 16 ft. tandem axle utility trailer is all

that's needed. It'll be low-cost and very economically to build, maintain,

and transport a truck of this type to and from the pull sites.

These

type of small pulling trucks would not cost nearly as much to build and maintain

as a traditional full-size (and high dollar) pulling truck. And it would

probably cost about the same or maybe less to build a 2WD or 4WD small wheel

pulling truck than it would cost to build a competitive garden pulling tractor.

In addition, unlike the full-size pulling trucks, which require a large,

heavy towing vehicle and a heavy duty goose-neck trailer to haul the truck

to and from the pull sites, these small and light-weight mini pulling trucks

require just a newer/late model 1/2 ton pickup truck (which have better braking

than earlier/older trucks) and a 16 ft. tandem axle utility trailer is all

that's needed. It'll be low-cost and very economically to build, maintain,

and transport a truck of this type to and from the pull sites.

If you decide to build one of these trucks for pulling yourself, it'll be best to use a mini pickup truck or an early model/vintage (pre-1955±) 1/2 ton pickup truck that weighs no more than 2,900 lbs. The most practical (short bed) mini trucks to use are: 1947-'55 Chevy/GMC 1/2 ton (with a 4 cylinder or V6 engine), Chevy LUV, Chevy S-10/Colorado, GMC S-15/Sonoma/Canyon, Ford Ranger, Toyota, Nissan Hardbody, Mitsubishi Mighty Max, Mazda B-Series, Jeep Comanche, Isuzu, Dodge Ram 50, etc.

For the two wheel drive (2WD) class, it's best to use a short wheelbase (approximately 108" from center of the front spindle to the center of the rear axle) truck because less forward weight will be transferred toward the rear tires, allowing the tires to dig in better for improved traction. And for the four wheel drive (4WD) class, it's best to use a long wheelbase (approximately 118" from center of the front axle to the center of the rear axle) truck because the extended forward weight will place more weight on the front tires, allowing them to have more traction for improved traction.

To build a mini class pulling truck like these, the basic necessities are:

-

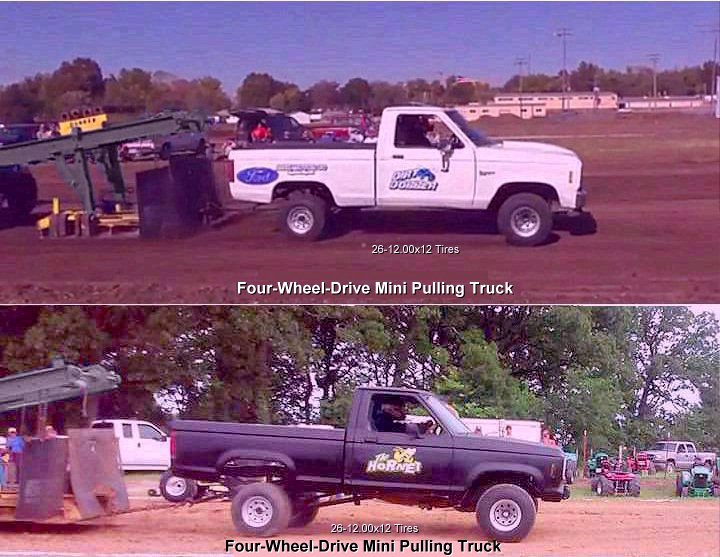

4-cylinder or V6 engine, naturally

aspirated carburetion or factory fuel injection. A V8 engine may add too

much weight to the truck to get into the weight class. Plus, it'll be about

40 lb. heavier on the front. And besides, the small 26-12.00x12 tires don't

need the power of a V8.

4-cylinder or V6 engine, naturally

aspirated carburetion or factory fuel injection. A V8 engine may add too

much weight to the truck to get into the weight class. Plus, it'll be about

40 lb. heavier on the front. And besides, the small 26-12.00x12 tires don't

need the power of a V8.

- Driveline: 1/2 ton two wheel drive or 4WD truck frame and differentials with an automatic or manual transmission.

- Rear Differential: For best traction for both the two wheel drive and 4WD trucks, use Limited-Slip or Positraction, Detroit Locker, mini spool, or weld spider gears together to lock both axles. The 4WD front differential carrier can be of locking or non-locking type (free-spinning spider gears).

- 26-12.00x12 front and rear professional pulling tires (minimum 4-ply rating). (Cepek, LawnTec, Nichols, Pit Bull, Vogel, etc.)

Exhaust Manifold or Header Pipe Mounting Gaskets VS Using Just Silicone Sealant Alone - Which Works Best?

Personally, whenever we install

exhaust manifolds or header pipes on an engine, we don't use gaskets. Instead,

we use RTV clear silicone sealant because silicone will not burn due to normal

or extreme exhaust heat. (Silicone can withstand up to 5,000º F.) Anyway,

gaskets always compress or "squeeze down" where the fastening bolts are,

causing the cast iron manifold to flex a few thousandths of an inch or thinner

steel header flanges to bend more than a few thousandths of an inch where

the mounting bolts are. When metal is compressed, the uncompressed area that's

between the bolts will allow the gasket(s) to leak and eventually burn out.

Also, before we install the manifolds or headers on an engine, we use a long,

wide flat file to make sure the mounting flanges on the manifolds or headers

are perfectly flat. Using silicone and the elimination of gaskets will allow

the manifolds or header flanges to be mounted flat against the cylinder heads,

creating absolute metal-to-metal contact, which also keep the mounting bolts

securely tight. The bolts will not loosen under any circumstances. Plus,

the silicone fills in the imperfections between the two metals, eliminating

any leaks. By the way - it's best to use

Clear RTV Silicone Adhesive Sealant for three reasons:

Gaskets don't always seal the irregularities between mating metals, especially

thin metal covers; being it's an adhesive, it bonds parts together, forming

a leak-proof seal; and being it's clear, it makes for a clean and

professional-looking repair job. When applied sparingly, it can't be easily

seen or noticed between the parts. Also, engine heat has very little effect

on silicone rubber. It can withstand up to 2,500 degrees heat.

Personally, whenever we install

exhaust manifolds or header pipes on an engine, we don't use gaskets. Instead,

we use RTV clear silicone sealant because silicone will not burn due to normal

or extreme exhaust heat. (Silicone can withstand up to 5,000º F.) Anyway,

gaskets always compress or "squeeze down" where the fastening bolts are,

causing the cast iron manifold to flex a few thousandths of an inch or thinner

steel header flanges to bend more than a few thousandths of an inch where

the mounting bolts are. When metal is compressed, the uncompressed area that's

between the bolts will allow the gasket(s) to leak and eventually burn out.

Also, before we install the manifolds or headers on an engine, we use a long,

wide flat file to make sure the mounting flanges on the manifolds or headers

are perfectly flat. Using silicone and the elimination of gaskets will allow

the manifolds or header flanges to be mounted flat against the cylinder heads,

creating absolute metal-to-metal contact, which also keep the mounting bolts

securely tight. The bolts will not loosen under any circumstances. Plus,

the silicone fills in the imperfections between the two metals, eliminating

any leaks. By the way - it's best to use

Clear RTV Silicone Adhesive Sealant for three reasons:

Gaskets don't always seal the irregularities between mating metals, especially

thin metal covers; being it's an adhesive, it bonds parts together, forming

a leak-proof seal; and being it's clear, it makes for a clean and

professional-looking repair job. When applied sparingly, it can't be easily

seen or noticed between the parts. Also, engine heat has very little effect

on silicone rubber. It can withstand up to 2,500 degrees heat.

Using 26-12.00x12 Pulling Tires/Wheels with Automotive Axles -

All 12" diameter wheels, rather for a garden tractor or small

utility trailer, come in the 4.5" x 5" bolt pattern (4-1/2" spacing with

5 bolt holes). An early model 8" or 9" Ford car axle flange will work with

12" garden tractor wheels because they have the same bolt pattern. The bolt

pattern that come in virtually every 12" diameter wheel center that have

5 mounting holes is 4-1/2". This size bolt pattern will work on Ford Ranger

mini trucks. But to use 12" wheels on a Chevy S10 or GMC Jimmy mini truck,

the centers can be adapted to a different bolt pattern (4-3/4") by drilling

five new holes between the existing 4-1/2" holes using a super spacer or

indexing fixture on the table of a large milling machine. 12" diameter wheel

blanks are available at

millertire.com. But to use a Ford truck or GM car or truck

axle with 12" garden tractor wheels, the centers will need to be cut out

of each wheel, and then true-up and weld-in the automotive centers in the

12" wheels. Make sure the offset back-spacing is set correctly, too. Go here:

Wheel Bolt Pattern Cross Reference Database and Conversion

Guide. To locate a set of wheels with the bolt pattern that's needed,

try a local automotive salvage yard, search eBay or Craigslist.

All 12" diameter wheels, rather for a garden tractor or small

utility trailer, come in the 4.5" x 5" bolt pattern (4-1/2" spacing with

5 bolt holes). An early model 8" or 9" Ford car axle flange will work with

12" garden tractor wheels because they have the same bolt pattern. The bolt

pattern that come in virtually every 12" diameter wheel center that have

5 mounting holes is 4-1/2". This size bolt pattern will work on Ford Ranger

mini trucks. But to use 12" wheels on a Chevy S10 or GMC Jimmy mini truck,

the centers can be adapted to a different bolt pattern (4-3/4") by drilling

five new holes between the existing 4-1/2" holes using a super spacer or

indexing fixture on the table of a large milling machine. 12" diameter wheel

blanks are available at

millertire.com. But to use a Ford truck or GM car or truck

axle with 12" garden tractor wheels, the centers will need to be cut out

of each wheel, and then true-up and weld-in the automotive centers in the

12" wheels. Make sure the offset back-spacing is set correctly, too. Go here:

Wheel Bolt Pattern Cross Reference Database and Conversion

Guide. To locate a set of wheels with the bolt pattern that's needed,

try a local automotive salvage yard, search eBay or Craigslist.

And we can't really give you a dollar amount to build a competitive two wheel drive or 4WD mini class pulling truck because building a mini-rod depends greatly on where you can find or purchase the parts, the quality of the parts, and their availability. If one owns their own auto salvage yard and/or an automotive machine/speed shop/business, and is a professional machinist and welder, then it shouldn't cost much at all to build their own mini class pulling truck. But if you don't possess these things, then it will cost a lot more. And as for the parts required to build a mini-rod, first, you will need a small truck cab and bed, a sturdy frame or chassis with the steering mechanisms and brakes, a 4-cylinder or V6 engine (because of their lightweight) in good condition, a lightweight automatic or manual transmission with a shielded flywheel, rear and front tires/wheels, centers out of the truck wheels to weld in the garden tractor wheels, various other parts, and lots of engineering to complete the truck and make it truly competitive on the track. Go here for videos: Check out our YouTube channel to see these pulling trucks in action. 2WD Pro Street Mini Pulling Trucks on YouTube.

By drilling a 3/32" hole through the thermostat plate, this will allow any air out of the block, especially when filling the radiator with coolant, and this hole will also let the engine to warm up faster by allowing the coolant make contact with the coil spring in the thermostat.

For inquiries, please contact:

Brian Miller of A-1 Miller's Performance Enterprises,

12091 N Route B, Hallsville, MO (Missouri) 65255-9604 USA.

![]() Phone:

1-573-881-7229 (cell; call, text or leave voicemail) or use

Whatsapp. Please call

any day, including holidays. If no answer, please try again later. (When

speaking with Brian on the phone, please be patient and understanding because

I stutter.)

Phone:

1-573-881-7229 (cell; call, text or leave voicemail) or use

Whatsapp. Please call

any day, including holidays. If no answer, please try again later. (When

speaking with Brian on the phone, please be patient and understanding because

I stutter.)

![]() E-mail:

pullingtractor@aol.com. A-1 Miller's

shop is open to the public everyday, including holidays. Please contact me

before coming so I'll be at my shop waiting for your arrival. When you visit

our shop, you will be dealing directly with the owner for the best customer

service. Location:

12091 N Route B, Hallsville, MO - Google Maps "The road

to a [trusted] friend's house (or shop) is never long." Don't sacrifice quality

workmanship for distance.

E-mail:

pullingtractor@aol.com. A-1 Miller's

shop is open to the public everyday, including holidays. Please contact me

before coming so I'll be at my shop waiting for your arrival. When you visit

our shop, you will be dealing directly with the owner for the best customer

service. Location:

12091 N Route B, Hallsville, MO - Google Maps "The road

to a [trusted] friend's house (or shop) is never long." Don't sacrifice quality

workmanship for distance.

Return To Previous Website | Top of Page

Copyright © This website created, designed and maintained by Brian Miller